Per day

Per day

Per day

Per day

We are entitled to clear Following upcoming inspections

PPB KENYA

TMDA TANZANIA

MINISTRY OF HEALTH OF ETHIOPIA

MINISTRY HEALTH OF UZBEKISTAN

ANVISA BRAZIL

MINISTRY OF HEALTH OF RWANDA

MINISTRY OF HEALTH OF TAJIKISTAN

MINISTRY OF HEALTH OF IRAQ

MINISTRY OF HEALTH OF YEMEN

MINISTRY OF HEALTH OF PHILIPPINES

- Machinery Details

- Utility Details

- Water Systems

- Quality System

- Instrumentation

| Machinery Name | Specification | Make |

|---|---|---|

| 01. RAPID MIXER GRANULATOR | 600 LTR & 150 LTR | SSMSL |

| 02. FLUID BED DRYER | 250 KG & 60 KG | SSMS |

| 03. OCTAGONAL BLENDER | 2000 LTR & 150 LTR | SSMS |

| 04. OCTAGONAL BLENDER | 600 LTR | SSMS |

| 05. AUTOCOATER I & II | "60"" & 36""" | SSMS |

| 06. TABLET PRESS I | 27D, 35B, 51D TOOLING | ACCURA |

| 07. TABLET PRESS II | 55 STN, B Tooling | CADMACH |

| 08. CAPSULE FILLING I | AF 90 T | ACG |

| 09. Capsule | CAPFILL 30 (SA 9) | CADMACH |

| 10. ALU/ALU BLISTER PACKAGING MACHINE | 200,000 UNITS/SHIFT | ACCURATE & PAM |

| 11. PVC/ALU BLISTER PACKING MACHINE | 500,000 UNITS/SHIFT | ELMACH |

| 12. Strip packing Machine | 4- Track | SATELLITE ENGINEERS |

| 13. OINTMENT MANUFACTURING PLANT | 300KG | SSMS |

| 14. OINTMENT FILLING | 25000 TUBE PER SHIFT | NPM |

| 15. SYRUP MANUFACTURING PLANT | 2000 LTS | SSMS |

| 16. LIQUID FILLING | 25000 TUBE PER SHIFT | NPM |

| 17. LABELLING MACHINE | 25000 TUBE PER SHIFT | NPM |

| Utility Name | Qty | Capacity |

|---|---|---|

| 01. Air Handing Unit | 44 | 800 - 13000 CFM |

| 02. Air Compressor | 1 | 165 CFM |

| 03. Diesel Generator Set | 2 | 62.3 KVA, 550 KVA |

| 04. Bolier | 1 | 600 KG/HR |

| 05. Chiller | 2 | 150 TR |

| 06, Reverse OSMOSIS Plant | 1 | 2000 LTR/HR |

| 07. Purified Treatment Plant | 1 | 2000 LTR/HR |

| 08. Effluent Treatment Plant | 1 | 35 KLD |

| 09. Air Compressor | 2 | 165 CFM |

| 10. Fire Tank | 1 | 96KL |

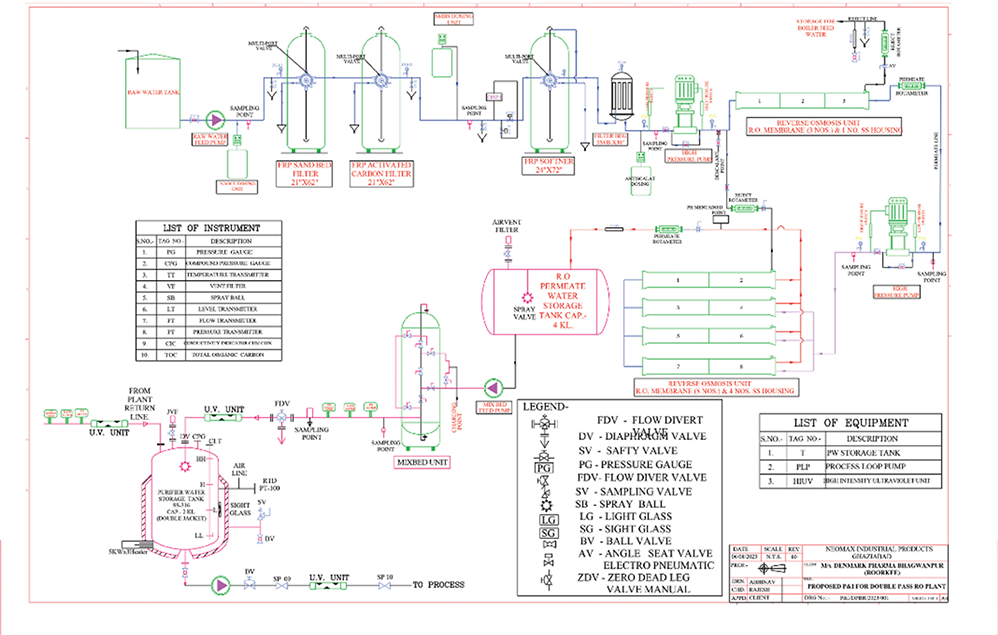

- Watersource: Ø 6 in., depth 290ft. bore well

- Overheadtank: 30,000 Its

- ROplant: 2,000 Its/hour

- Purified water plant: 2,000 lts/hour

- Loopline: Ø 1 in., MOC SS 316

- Zerodeadlegvalve: Ø 1 in., MOC SS 316L

Equipped with the latest testing equipments and backed by qualified and experienced staff, the Quality control and in-process quality control departments ensure that our products are of top quality.

We follow all the GLP and GMP practices to deliver you the top quality products that are equivalent to formulations from multinational companies.

Our manufacturing plant, machinery and processes are compliant with the standards laid down by CFR - Code of Federal Regulations Title 21 part 11.

| Instrumentation Name | Area (sq. mt) |

|---|---|

| 3 HPLC | Waters alliance e2695 |

| 3 HPLC | Agilent 1260 |

| UV | Agilent |

| IR | Agilent |

| IR Moisture Balance | Shimandzu |

| Analytical Balance | Shimandzu & Ohash |

| 2 Dissolution Apparatus | Electro Lab |

| HPLC Water assembly | Watman |

| Autoclave Horizontal & Vertical | Watman & Effem |

| Incubator | Effem |

| 3 Walk-in Stability Chamber 8000 Ltr | Kesar |

| 2 Stability Chamber 1000 Ltr | Kesar |